To All,

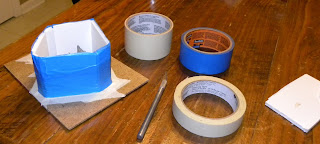

Alright, the box is set and ready to make the mold.

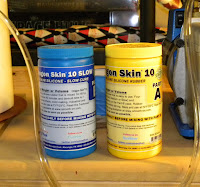

For most of my molds I use Smooth-On Dragon Skin 10 Slow. Dragon Skin is a softer and more more pliable than other Smooth-on products and I go with the "Slow" because I'm going to use the a vacuum chamber and I prefer the 45 minute pot life so I am not rushed.

I am using a CoolTech vacuum pump and an ArtMolds vacuum Chamber. I have been using these for years and they are both reliable and easy to use.

The Dragon Skin is easy to use and measures at a 1:1 ratio. I mix part A and Part B in a stainless steel bowl. The stainless steel bowl is great in the vacuum chamber and can be used over & over again because the cured mold rubber just peels right off of it.

You can see the bubbles in the rubber after mixing parts A and B.

Into the vacuum chamber to draw all bubbles/air out of the liquid rubber.

The rubber rises, the bubbles rise up and release, and then the rubber collapses on itself.

Ready to pour...

A generous spray of Mann Ease Release 200 into the box.....

...and then a pour from height. The reason for this is two-fold; bubbles pop in the thin steam pouring from the bowl into the mold, and bubbles don't get trapped around the figures as the rubber rises slowly around the figures.

Into the vacuum chamber to pull out the remaining air...

....and the mold will set overnight.

More to come.